Entering the UK market around five years ago, hybrid buses such as the Volvo B5L and LF are now commonplace in operator fleets delivering urban services with stringent environmental controls, such as Transport for London’s Ultra Low Emissions Zone, which operates 24 hours a day.

Hybrid Buses

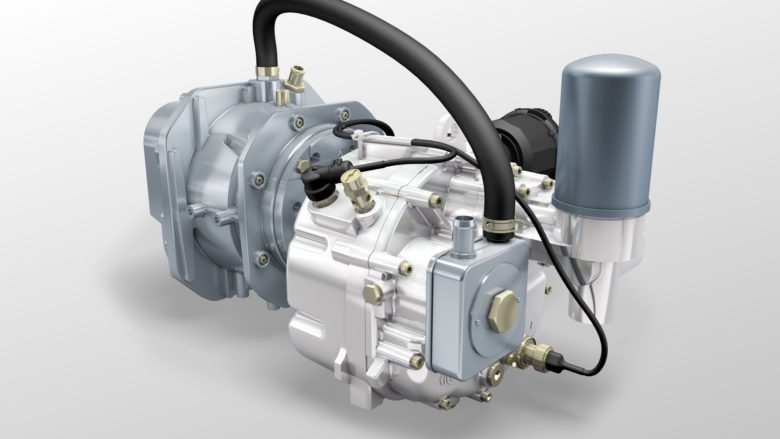

Although visually similar to a conventional diesel bus, hybrid buses are fundamentally different when it comes to producing the compressed air needed for air braking, pneumatic suspension and door opening systems. While diesel-powered buses use engine-driven air compressors, hybrids typically feature standalone electrically driven screw and vane compressors from OEMs, including Knorr-Bremse and Gardner Denver, to supply constant and stable compressed air.

Unlike diesel-driven compressors that are lubricated and cooled by the engine’s oil circuit, electric hybrid compressors feature an independent lubrication system. As a result, these systems require regular oil and filter changes in line with the compressor manufacturer’s recommendations and a vehicle’s duty cycle to ensure the intended service life of the system. Conventional compressors require minimal maintenance, are designed to provide an average service life of five years and cost around £500 to replace, depending on the make and model of the vehicle. In comparison, standalone electrically driven screw and vane compressors can cost up to ten times more than their diesel-driven counterparts to replace.

As a result, maximising the service life of electric compressors has become a key consideration for operators seeking to run their hybrid fleets as efficiently as possible. Research undertaken by Imperial Engineering has found that major contributors to component failure are excessive oil carry resulting in oil leaks and dirt ingress into the compressor’s drive motor causing bearing damage, leading to the compressor running very hot and ultimately failing.

To address this problem, Imperial Engineering recommends that operators increase the inspection and service of electric compressors on a regular basis, in line with the OE manufacturer recommendations and local duty cycles. By increasing hybrid compressor maintenance, including regular oil and filter changes, operators can increase service life, reducing the overall operating cost of the compressor.

To help make the servicing of hybrid compressors easier and more cost-effective for operators, Imperial Engineering has recently introduced a range of service kits. These feature Knorr-Bremse OE filters and the correct grade of synthetic Volvo B5 Hybrid Compressor Oil, which is available in one or 20 litre containers. Imperial Engineering has a wealth of compressor system knowledge and is pleased to support operators with technical advice and guidance. For further information, please call 01992 634255 or email enquiries@imperialengineering.co.uk