Knorr-Bremse Group is a leading global manufacturer of braking systems for rail, public service and commercial vehicles. For over 110 years Knorr-Bremse UK has pioneered the development, production and servicing of bus and coach air braking systems in the UK.

Knorr-Bremse

Knorr-Bremse product range includes

An innovative developer of advanced electronic and pneumatic systems, Knorr-Bremse UK supplies OE braking systems to all leading PSV manufacturers and has a network of Knorr-Bremse suppliers, which Imperial Engineering is proud to be part of.

Imperial Engineering is proud to partner this highly regarded and world-wide established organisation. The various proven and sought after Knorr-Bremse parts form part of the Imperial Engineering catalogue of products all ready and available for bus and coach repairs to be dispatched via our distribution centre based at our head office in Cheshunt, Essex.

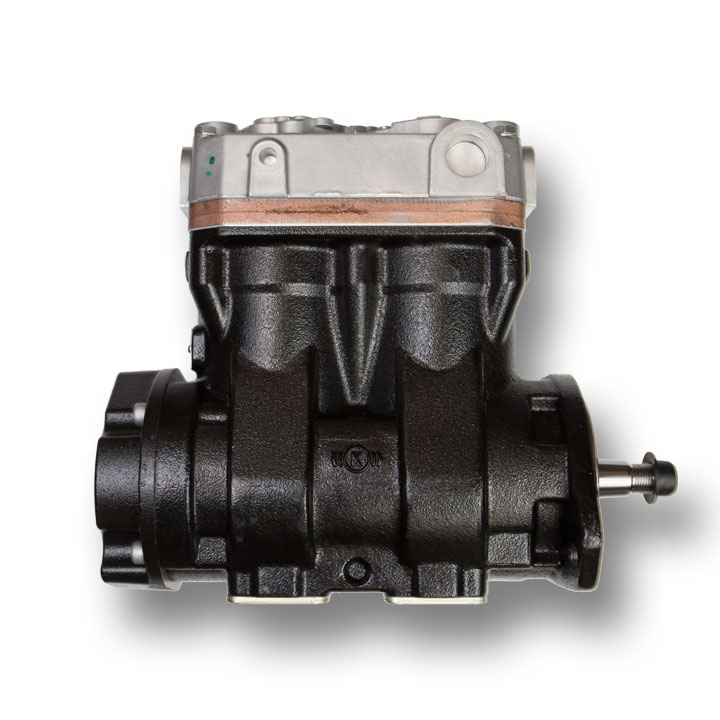

Compressors

Compressed air, delivered via a compressor powered by the engine, is the main source of energy for all pneumatic braking systems, air suspension systems and clutches used in Public Service Vehicles (PSV).

Knorr-Bremse UK manufactures a wide range of compressor systems, including flange mounted units with direct gear drive, or base mounted compressors with belt drive. These products can be supplied by Imperial Engineering with an optional energy-saving system (ESS).

Valves

Knorr-Bremse valves enable precise control of the supply of compressed air to the braking and suspension systems for both buses and coaches. Supplied by leading Knorr-Bremse UK parts distributor for over 25 years, Imperial Engineering, the range includes:

- Foot brake valves

- Hand brake valves

- Relay valves

- Brake pressure regulators

- Air suspension valves

Pedal units with integrated clutch actuation systems are also part of the Knorr-Bremse UK range of valves.

These Plug-and-Play modules offer customers significant technical as well as logistical advantages. To discuss these in more detail, please contact a member of our team today.

EBS Control Modules

Knorr-Bremse is a global market leader in the development of active and passive driver assistance systems. The product range includes ABS (anti-lock braking systems) and EBS (electronic braking systems).

EBS (electronic braking systems) control modules integrate the functions of braking control, ABS and ASR (traction control), into one electronic system.

The advantages of electronic control over conventional pneumatic control are shorter response time and braking distance, resulting in increased road safety.

Spring Brakes (rear) and Brake Chambers (front) and Brake Discs

The brake actuator converts pneumatic energy into mechanical energy. This results in the friction material being pressed against the brake contact surfaces, causing the vehicle to slow down or stop.

Brake Actuator

During braking, or in the case of a change of load, the compressed air is directed via control valves and/or control modules to the brake actuators or suspension bellows, at pressures over 10 bar.

For buses and coaches, Knorr-Bremse’s modular brake cylinder concept is applicable to all uses, covering vehicles of all different sizes and performance.

Due to its modular design by Knorr-Bremse’s technical specialists, the number of individual braking components has been greatly reduced, which reduces customer expenditure on replacement parts and maintenance.

Quality, safety, reliability and the environment are issues of great importance to Knorr-Bremse UK

Imperial Engineering has been an Authorised Distributor for Knorr-Bremse bus and coach parts for over 25 years. Customers demand the highest standards and both Imperial Engineering and Knorr-Bremse UK have built up respected reputations for being leaders in their field.

Imperial Engineering is your premium KNORR-BREMSE PARTS SUPPLIER across London, Essex, Hertfordshire and the rest of the UK.

We invite all bus and coach operators in need of Knorr-Bremse parts to contact Imperial Engineering for a knowledgeable, fast, friendly and highly competitive service.

Why not search the range of Knorr-Bremse parts available at Imperial Engineering

You can also contact one of the Imperial Engineering team who will be happy to help advise and assist with any Knorr-Bremse parts enquiry. Offering the entire product catalogue of Knorr-Bremse parts for dispatch across the UK, Imperial Engineering is your one stop shop for Knorr-Bremse parts for bus and coach repair.