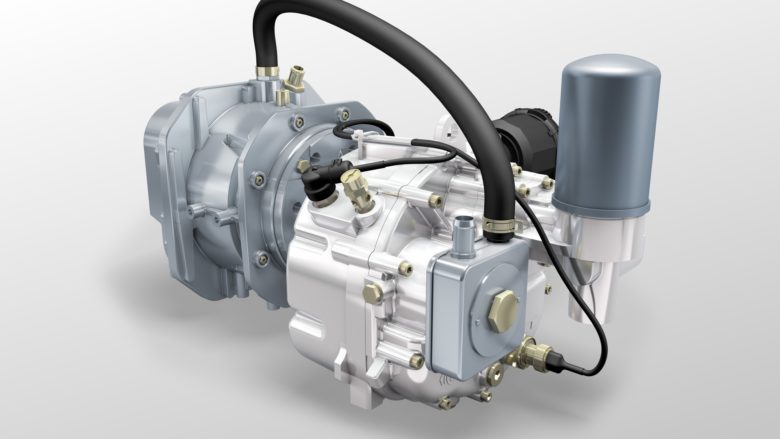

e-compressors and mechanical compressors

Imperial Engineering possesses a wealth of knowledge when it comes to the routine maintenance of bus systems. However, the leading PSV parts distributor has been somewhat surprised by the unexpectedly high failure rate of e-compressors fitted to newer diesel-powered buses when compared to conventional mechanical piston compressors.

John Simmons, Imperial Engineering’s Sales Manager, comments:

“It’s fair to say that over the years we have seen many issues with the older types of mechanical compressors. Although maintenance free, as they rely on lubrication from the engine oil and clean air supplied by the air filtration system, the high operating temperature and poor quality air can lead to oil carry over into the air system. This eventually causes carbon build-up and component failure, usually starting with the air dryer and supply pipes.

“In comparison, e-compressors have their own lubrication circuit, using high-quality fully synthetic oil. As a result, it is imperative that the operators service e-compressors in accordance with the vehicle and compressor manufacturer’s recommendations, using the correct specification and grade of oil at a frequency that is commensurate with the vehicle’s duty cycle.

“While we are not seeing oil carry over into the air system or air dryer failures on e-compressors, we are instead observing drive motor failures, due to compressors overheating in some installations. This causes the component to seize, as well as heat damage to the drive motor and in some instances, dirt ingress. Alongside potential reliability problems and higher maintenance costs for operators, the replacement cost of e-compressors for hybrid and electric bus applications is currently six times greater than the cost of replacing a conventional unit.

Imperial Engineering is currently working with OE compressor suppliers to examine ways of improving e-compressor service life, in order to reduce maintenance costs.

Based on current investigations, Imperial Engineering recommends increasing the frequency of e-compressor inspections to monthly. This will help to minimise the risk of problems associated with air or oil leaks, as well as checking the oil level and topping up regularly and ensuring the external cooling fans are operating correctly. Overall, Imperial Engineering recommends increasing e-compressor servicing intervals from annually to three or four times a year, as this is the best practical option to increase of e-compressor service life.

Imperial Engineering has a wealth of compressor system knowledge and is pleased to support operators with technical advice and guidance.